The PowerFlex 755 Programming Manual provides a comprehensive guide for configuring and optimizing the drive’s advanced features․ Designed for programmers and engineers‚ it covers essential setup‚ motion control‚ and integration with Rockwell Automation systems‚ ensuring efficient and safe operation of the drive in various industrial applications․

1․1 Overview of the PowerFlex 755 Drive

The PowerFlex 755 is a high-performance AC drive designed for industrial automation‚ offering advanced motor control and flexible integration․ It supports high-power applications with precise speed regulation and energy efficiency․ The drive features an embedded EtherNet/IP adapter for seamless connectivity with Rockwell Automation systems․ Its robust design ensures reliable operation in demanding environments‚ making it suitable for various industries requiring precise motor control and efficient performance․

1․2 Importance of the Programming Manual

The PowerFlex 755 Programming Manual is essential for engineers and technicians to optimize drive performance․ It provides detailed instructions for configuring parameters‚ integrating with Rockwell Automation systems‚ and implementing safety features like Safe Torque Off․ The manual ensures proper setup‚ troubleshooting‚ and maintenance‚ helping users maximize efficiency and safety in industrial automation applications․ Adhering to its guidelines minimizes downtime and enhances overall system reliability and productivity․

Hardware Installation and Setup

This section outlines the mechanical and electrical installation procedures for the PowerFlex 755 drive‚ ensuring compliance with safety standards and compatibility with Rockwell Automation systems․

2․1 Mechanical Installation Guidelines

Proper mechanical installation is critical for the PowerFlex 755 drive’s performance and longevity․ Ensure the drive is mounted securely on a flat surface‚ aligned correctly‚ and fastened tightly to prevent vibration․ Refer to the ATEX user manual for explosion-proof environments․ Follow torque specifications for screws and connectors to avoid damage․ Use appropriate cable management systems to maintain neatness and safety․ Compliance with Rockwell Automation’s mechanical standards ensures reliable operation and minimizes downtime․

2․2 Electrical Installation and Wiring

Ensure proper electrical installation by following the PowerFlex 755 drive’s wiring diagrams and guidelines․ Connect power and motor cables securely‚ verifying polarity and phase sequence․ Use appropriately sized conductors and ensure proper grounding for noise reduction and safety․ Insulate all connections to prevent short circuits․ Refer to Rockwell Automation’s wiring standards for compliance․ Double-check all connections before power-up to avoid damage or malfunction․

Software Configuration

The PowerFlex 755 drive’s software configuration involves setting up the Studio 5000 environment and configuring motion instructions for precise motor control and seamless integration with Rockwell Automation systems․

3․1 Studio 5000 Environment Setup

Setting up the Studio 5000 environment involves installing and configuring the software to integrate with the PowerFlex 755 drive․ This includes enabling motion instructions and ensuring compatibility with Rockwell Automation systems․ The software provides tools for programming‚ monitoring‚ and optimizing drive performance․ Proper setup ensures seamless communication and control‚ leveraging the drive’s advanced features for high-performance applications․ Follow the manual’s instructions to install and configure the environment correctly․

3․2 Motion Instructions for PowerFlex 755

Motion instructions within Studio 5000 enable precise control of the PowerFlex 755 drive‚ allowing for advanced motor synchronization and positioning․ These instructions are shared with Kinetix servo systems‚ ensuring compatibility and flexibility․ By utilizing predefined commands‚ users can automate complex movements‚ optimize performance‚ and integrate seamlessly with Rockwell Automation controllers․ This feature enhances productivity and reduces programming complexity in industrial automation applications․

Programming and Parameter Settings

Configure motor parameters and Safe Torque Off (STO) settings to ensure precise control and safety․ Adjust drive settings to optimize performance and meet application-specific requirements effectively․

4․1 Configuring Motor Parameters

Accurate motor parameter configuration is crucial for optimal drive performance․ Enter motor nameplate data‚ including rated speed‚ torque‚ and current‚ using Studio 5000 software․ Adjust inertia and load type settings to match application requirements․ Proper configuration ensures precise speed and torque control‚ minimizing mechanical stress and maximizing efficiency․ Refer to the motor manufacturer’s specifications for exact values to ensure accurate setup and reliable operation of the PowerFlex 755 drive․

4․2 Setting Up Safe Torque Off (STO)

Safe Torque Off (STO) is a critical safety feature that disables the drive’s torque output‚ ensuring operator safety during maintenance or emergencies․ To configure STO on the PowerFlex 755‚ enable the feature in the drive’s parameters and connect the STO input according to the wiring diagram․ Verify compliance with IEC 61508 standards and test the functionality to ensure proper operation․ Always follow safety protocols when implementing STO to prevent accidents and ensure regulatory compliance․

Integration with Rockwell Automation Systems

The PowerFlex 755 seamlessly integrates with Rockwell Automation systems via EtherNet/IP adapters‚ enabling efficient communication and control․ Compatible with Logix Designer‚ it ensures advanced automation solutions․

5․1 EtherNet/IP Adapter Configuration

The EtherNet/IP adapter enables seamless communication between the PowerFlex 755 drive and Rockwell Automation controllers․ Configuration involves setting IP addresses‚ subnet masks‚ and gateway parameters․ Studio 5000 software simplifies parameter setup‚ ensuring compatibility with Logix Designer․ Proper network configuration ensures real-time data exchange‚ diagnostics‚ and control․ Refer to Rockwell Automation’s publication 750-PM001Q-EN for detailed instructions and troubleshooting guidelines․ Proper setup is crucial for optimal performance and integration․

5․2 Compatibility with Logix Designer

The PowerFlex 755 drive seamlessly integrates with Logix Designer‚ enabling efficient programming and control within the Studio 5000 environment․ This compatibility allows for advanced motion control and synchronized operations‚ ensuring precise and reliable performance․ Proper configuration and setup are essential for optimal integration‚ as outlined in Rockwell Automation’s guidelines․ This compatibility streamlines industrial automation processes‚ enhancing productivity and system responsiveness․

Safety Precautions and Compliance

Understand safety ratings‚ standards‚ and operating practices to ensure compliance․ Always follow manual guidelines for safe installation‚ operation‚ and maintenance to prevent hazards and ensure reliable performance․

6;1 Understanding Safety Ratings and Standards

Understanding safety ratings and standards is crucial for safe operation․ The manual highlights warnings and cautions to prevent hazards‚ such as explosions in hazardous environments․ It outlines compliance with industry standards like ATEX and UL‚ ensuring the drive meets safety requirements․ Proper interpretation of symbols and notations ensures adherence to safety protocols‚ minimizing risks during installation‚ operation‚ and maintenance of the PowerFlex 755 drive․

6․2 Implementing Safe Operating Practices

Implementing safe operating practices is essential for ensuring the longevity and reliable operation of the PowerFlex 755 drive․ Always follow Rockwell Automation’s guidelines for installation‚ operation‚ and maintenance․ Use proper protective equipment and adhere to lockout/tagout procedures during servicing․ Regularly inspect electrical connections and ensure compliance with environmental and safety regulations․ Proper training and adherence to safety protocols minimize risks and ensure a safe working environment for personnel interacting with the drive․

Troubleshooting Common Issues

Troubleshooting the PowerFlex 755 involves identifying and resolving hardware faults and software configuration errors․ Use diagnostic tools and error codes to pinpoint issues and apply corrective actions․

7․1 Diagnosing Hardware Faults

Diagnosing hardware faults on the PowerFlex 755 involves checking error codes‚ LED indicators‚ and system logs․ Use Studio 5000 software to monitor drive status and identify malfunctions․ Verify wiring connections and ensure proper installation․ Consult the maintenance manual for detailed troubleshooting procedures and replace faulty components as needed to restore optimal drive performance and prevent downtime in industrial applications․

7․2 Resolving Software Configuration Errors

Resolving software configuration errors in the PowerFlex 755 involves verifying parameter settings and updating firmware․ Use Studio 5000 to review motion instructions and ensure compatibility with Logix Designer․ Check for communication issues with EtherNet/IP adapters and refer to Rockwell Automation publications for detailed troubleshooting steps․ Correcting software errors ensures seamless integration and optimal performance of the drive in industrial automation systems․

Maintenance and Updates

Regular maintenance ensures optimal performance․ Schedule routine checks‚ update firmware via Studio 5000‚ and refer to Rockwell Automation resources for detailed procedures and support․

8․1 Routine Maintenance Procedures

Regular maintenance is crucial for the PowerFlex 755’s longevity and performance․ Inspect the drive’s electrical connections‚ clean dust from heat sinks‚ and ensure proper cooling․ Refer to the Rockwell Automation manual for detailed procedures․ Check for firmware updates and perform backups before any software changes․ This ensures optimal operation and prevents unexpected downtime in industrial applications․

8․2 Updating Firmware and Software

Updating the PowerFlex 755’s firmware and software ensures optimal performance and compatibility․ Use Studio 5000 to download and install the latest versions from Rockwell Automation’s official website․ Always back up configurations before updating to prevent data loss․ Follow the manual’s step-by-step instructions to avoid errors during the process‚ ensuring a smooth transition to new features and improvements․

Advanced Features and Capabilities

The PowerFlex 755 offers high-performance motor control‚ flexible I/O integration‚ and advanced network connectivity‚ enhancing industrial automation systems with precision and efficiency for demanding applications․

9․1 High-Performance Motor Control

The PowerFlex 755 drive delivers high-performance motor control with precise speed regulation and advanced torque control․ It supports adaptive tuning for optimal motor performance and includes motion instructions within the Studio 5000 environment․ This ensures seamless integration with Rockwell Automation systems‚ enabling efficient control of high-demand applications․ The drive’s capabilities enhance operational reliability and efficiency‚ making it ideal for complex industrial automation tasks․

9․2 Flexible I/O and Network Integration

The PowerFlex 755 drive offers flexible I/O and network integration through its EtherNet/IP adapter‚ enabling seamless communication with Rockwell Automation systems․ It supports multiple industrial protocols‚ including EtherNet/IP‚ DeviceNet‚ and ControlNet‚ ensuring compatibility across diverse applications․ The drive’s integration with Logix Designer simplifies programming and configuration‚ while its adaptability to various network topologies enhances scalability and performance in industrial automation environments․

User Manual Conventions and Symbols

This section explains the notations‚ symbols‚ and conventions used throughout the manual to guide users effectively․ It includes warnings‚ cautions‚ and references to diagrams for clarity․

10․1 Understanding Manual Notations

This section details the notations used in the manual‚ such as warnings‚ cautions‚ and notes‚ ensuring clear understanding․ Symbols and abbreviations are explained to prevent confusion․ References to specific Rockwell Automation publications are included for further guidance․ Proper interpretation of these notations is crucial for safe and effective use of the PowerFlex 755 drive․

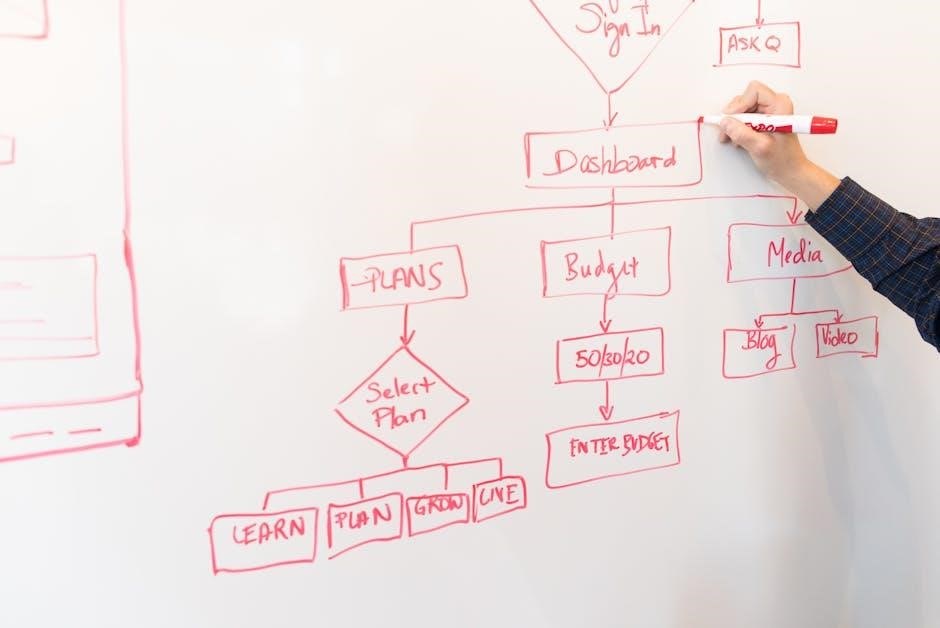

10․2 Interpreting Diagrams and Schematics

Diagrams and schematics in the manual provide visual representations of hardware and software configurations․ They include wiring layouts‚ motor connections‚ and control circuits‚ using color-coding and symbols for clarity․ These visuals aid in understanding installation‚ troubleshooting‚ and integration processes․ Referencing these diagrams ensures accurate setup and alignment with Rockwell Automation standards‚ helping users avoid errors and ensure safe‚ efficient operation of the PowerFlex 755 drive․

Additional Resources and References

This section provides a directory of Rockwell Automation publications‚ including technical guides‚ user manuals‚ and online support resources for the PowerFlex 755 drive․

11․1 Supplementary Rockwell Automation Publications

Rockwell Automation offers additional resources‚ including the PowerFlex 750-Series ATEX User Manual and Studio 5000 setup guides․ These publications provide detailed instructions for installation‚ configuration‚ and troubleshooting․ They also cover firmware updates‚ compatibility with Logix Designer‚ and safety compliance․ The manuals include diagrams‚ wiring schematics‚ and best practices for optimizing drive performance․ These resources ensure comprehensive support for programmers and engineers working with the PowerFlex 755 drive․

11․2 Online Support and Documentation

Rockwell Automation provides extensive online resources‚ including PDF manuals‚ user guides‚ and technical notes for the PowerFlex 755․ These documents are accessible via their official website and offer detailed troubleshooting‚ configuration‚ and programming guidance․ Additionally‚ online forums and technical support portals are available for resolving specific issues or clarifying drive functionality‚ ensuring users have comprehensive support for their programming needs․

Applications and Best Practices

The PowerFlex 755 is ideal for high-performance motor control in industrial automation‚ offering flexible I/O and network integration․ Best practices include optimizing drive settings for specific applications and following Rockwell Automation guidelines for safe and efficient operation․

12․1 Optimizing Drive Performance

Optimizing PowerFlex 755 performance involves fine-tuning motor parameters‚ leveraging motion instructions‚ and enabling advanced features like Safe Torque Off․ Utilize Studio 5000 to adjust settings for precise control and efficiency․ Regularly updating firmware ensures access to the latest enhancements․ Refer to Rockwell Automation resources for detailed tuning guides and application-specific optimizations to maximize drive capabilities in industrial automation systems․

12․2 Case Studies and Real-World Applications

Real-world applications highlight the PowerFlex 755’s versatility in industrial automation․ Case studies demonstrate its effectiveness in high-performance motor control‚ precise motion synchronization‚ and seamless integration with Rockwell Automation systems․ Examples include advanced material handling‚ high-speed packaging‚ and energy-efficient manufacturing processes․ These studies showcase how the drive’s flexibility and reliability optimize production workflows‚ reduce downtime‚ and enhance overall system performance in diverse industrial environments․